- Home

- Products

- Testing and Taping Machine

- Simplified Inductor Automatic Tape and Reel Machine

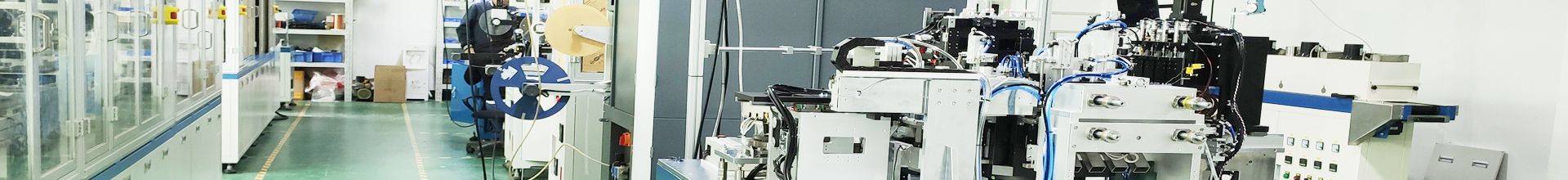

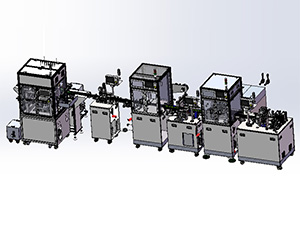

Simplified Inductor Automatic Tape and Reel Machine

JDL simplified inductor Automatic Tape and Reel Machine performs the testing and reel packing of inductor products. It adopts manual feeding, also available in automatic feeding mode. Manipulator is used to take products for electrical performance test. Positing accuracy is controlled within 0.05mm. It can also test the inductors’ RDC/L. After the testing, this machine packs the inductors, optional in cold seal and hot seal. PLC control system ensures stable temperature and accurate counting. Besides, its abnormity alarm and baking system guarantees the safety in the processing.

| Feeder | Manual feeding(or programmable with controller) |

| Packaging Method | Automatically |

| Testing Project | RDC/L (customized) |

| Position Accuracy | ±0.05mm |

| Capacity | 5-8Kpcs/H |

| Testing Speed | 4-6.5Kpcs/H |

| Control Method | PLC controlled |

| Working environment | -5℃-50℃(No corrosive gas, harmful gas, flying dust, etc.) |

| Size(L*W*H) | 650 X 750x 1500mm |

| Power supply | Single phase AC220V/50HZ |

| Air supply | 0.5—0.7mpa |

| Power consumption | 1.2kW |

| Weight | About 150kg |

JDL has devoted itself in the field of electric motor rewind, serving an extensive portfolio from coil winding equipment to electrical safety test equipment.

For over a decade, JDL has been specialized in manufacturing and supplying engineering solutions and equipment to the wire processing and electrical industries. We strive to pay close attention to the needs of our customers and move forward by designing and producing optimal winding machines and peripheral equipment.

- Area B, Third Floor, No. 2 Nanjiang Industry, Tongsheng Community, Dalang Street, Longhua District, Shenzhen

- +86-755-29370700