- Home

- Products

- Other Equipment

- Automatic Automatic Common Mode Choke Assembly Machine

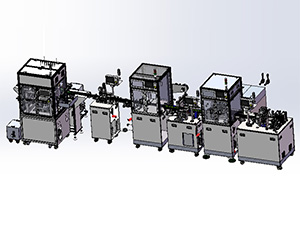

Automatic Common Mode Choke Assembly Machine

Model: AM-GMZZ-10

Application: Dispense the core of common mode choke and assemble the upper cover.

Performance and Parameter

| Feeding Mode: | Automatic Feeding (Can be customized to tray feeding, vibration bowl feeding, and other modes according to customer’s requirements) |

| Dislocation Between Magnetic Core and Cover: | ± 0.07mm |

| Machine Capacity: | 2.8-3.6KPCS / H (depending on product size and dispensing time) |

| Applicable Products: | Common Mode Choke (Common Mode Choke Series) |

| Operation Control Mode: | Imported PLC control, intuitive and simple HMI which can meet the requirements of numerical control and humanization. |

| Working Environment: | -5 ℃ ~ 50 ℃ (no corrosive harmful gas, no flying dust and other harsh environments) |

| Machine Size: | L1500 mm* W1400mm*H1750mm |

| Power Supply: | AC220V / 50HZ |

| Air Supply: | 0.4 ~ 0.7MPa |

| Power: | 5.5KW (Including the Power of Industrial Tunnel Oven) |

| Machine Weight: | about 400KG |

| Machine Features: | 1) High versatility, other common mode products can be assembled by change some special parts. Easy to learn and operate. 2) The 8 stations on the turret are driven by direct drive motor. Precise segmentation and positioning. 3) Many choices for feeding modes. Reasonable structure and high use efficiency. |

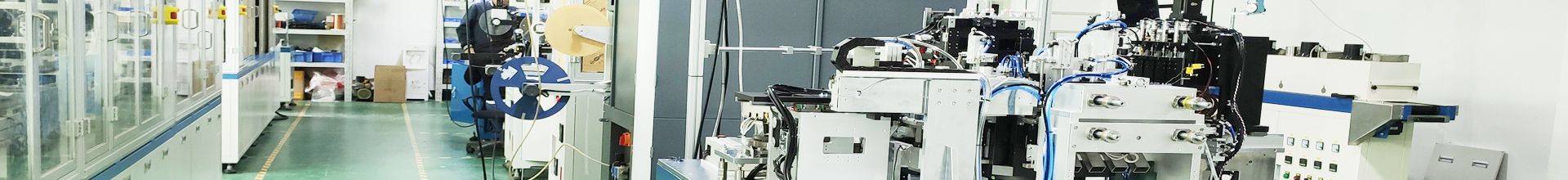

Product Details:

Other Products for Your Production Line

For sales or more information Contact us here

JDL has devoted itself in the field of electric motor rewind, serving an extensive portfolio from coil winding equipment to electrical safety test equipment.

For over a decade, JDL has been specialized in manufacturing and supplying engineering solutions and equipment to the wire processing and electrical industries. We strive to pay close attention to the needs of our customers and move forward by designing and producing optimal winding machines and peripheral equipment.

Products

- Area B, Third Floor, No. 2 Nanjiang Industry, Tongsheng Community, Dalang Street, Longhua District, Shenzhen

- +86-755-29370700