- Home

- Products

- Other Equipment

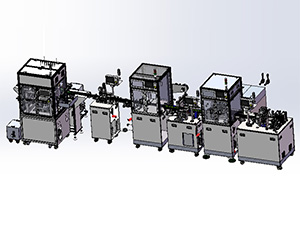

- AM-SXL-20 Loading-Unloading System

Loading-Unloading System

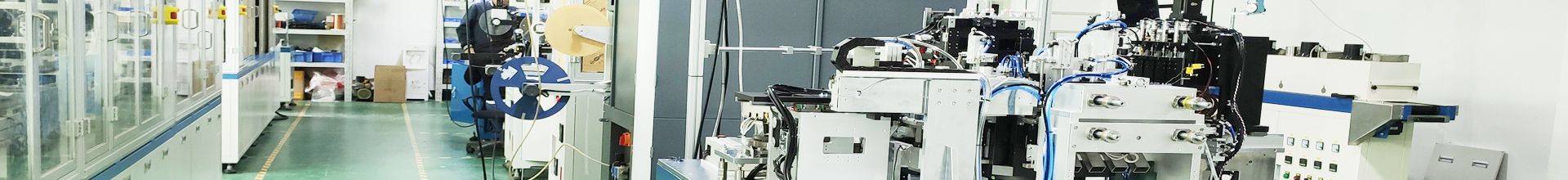

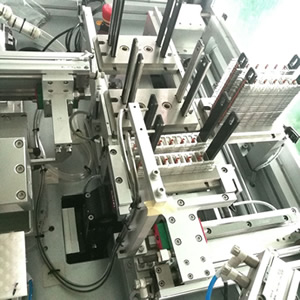

JDL loading-unloading system is designed for the manufacturing of molded inductor, which automatically feeds inductors, trims molded inductor and automatically unloads them after testing and packing. A PLC control system and warning system ensures the production safety during the operation and improves the efficiency of assembly line.

| Feeder | Magazine |

| Unloading Mode | Pallet/Magazine(optional) |

| Application | Molded inductor or injection molded parts |

| Accuracy | 0.02mm |

| Capacity | 0.6-0.8 Kpcs/h |

| Working temperature | -5℃-50℃ |

| Machine size(L*W*H) | 1200(L)*800(W)*1800(H)mm |

| Power supply | Single phase, AC220V/50HZ |

| Air supply | 0.4-0.6mpa |

| Power consumption | 5kW |

| Weight | 400kg |

JDL has devoted itself in the field of electric motor rewind, serving an extensive portfolio from coil winding equipment to electrical safety test equipment.

For over a decade, JDL has been specialized in manufacturing and supplying engineering solutions and equipment to the wire processing and electrical industries. We strive to pay close attention to the needs of our customers and move forward by designing and producing optimal winding machines and peripheral equipment.

- Area B, Third Floor, No. 2 Nanjiang Industry, Tongsheng Community, Dalang Street, Longhua District, Shenzhen

- +86-755-29370700