- Home

- Products

- Winding Machine

- NR Series Winding and Glue Dispensing All-in-One Machine

NR Series Winding and Glue Dispensing All-in-One Machine

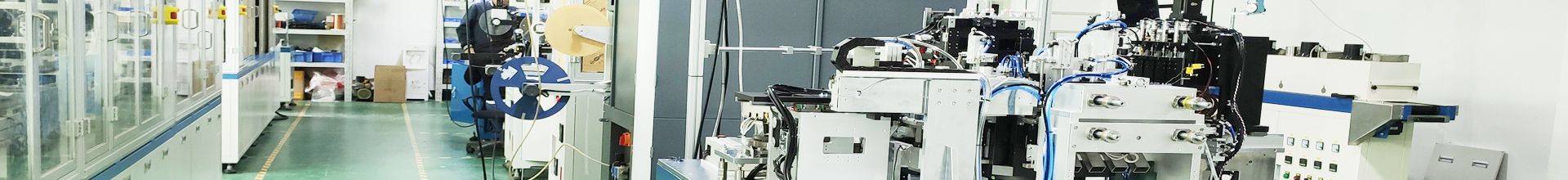

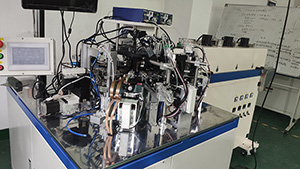

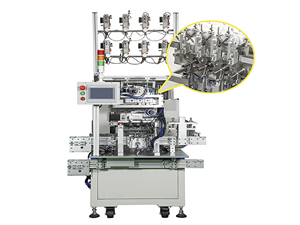

JDL NR series winding and glue dispensing all-in-one machine is specially designed to wind coils for NR series ferrite core inductors and it also functions broadside soldering. Thus, it can perform winding and soldering simultaneously. It features a maximum winding speed of 4000rpm and can handle wires with a diameter of 0.06-0.25mm. PLC control allows technical accuracy and simple operation. Features include perfect gluing effect, settable baking time and over-temperature alarm function, which ensures the product’s pass rate. In addition, unloading is flexible in discharging the product to trays or directly.

| Application | Ferrite core inductor |

| Feeder | Vibratory bowl feeder |

| No. of spindles | 1 |

| Winding method | Single winding |

| Wire size | 0.06-0.25mm |

| Max. Winding Speed | 4000rpm/min |

| Control system | PLC |

| Capacity | 1.2~1.8Kpcs/H |

| Dimensions(mm) | 2500*1200*1600mm(L*W*H) |

| Air supply | 0.5-0.7Mpa |

| Working environment | -5℃-50℃(No corrosive gas, harmful gas, flying dust, etc.) |

| Power supply | Single phase AC220V/50HZ |

| Power consumption | 9kW |

| Net Weight | 500kg |

JDL has devoted itself in the field of electric motor rewind, serving an extensive portfolio from coil winding equipment to electrical safety test equipment.

For over a decade, JDL has been specialized in manufacturing and supplying engineering solutions and equipment to the wire processing and electrical industries. We strive to pay close attention to the needs of our customers and move forward by designing and producing optimal winding machines and peripheral equipment.

- Area B, Third Floor, No. 2 Nanjiang Industry, Tongsheng Community, Dalang Street, Longhua District, Shenzhen

- +86-755-29370700