- Home

- Products

- Winding Machine

- Common Mode Choke Coil Winding Machine

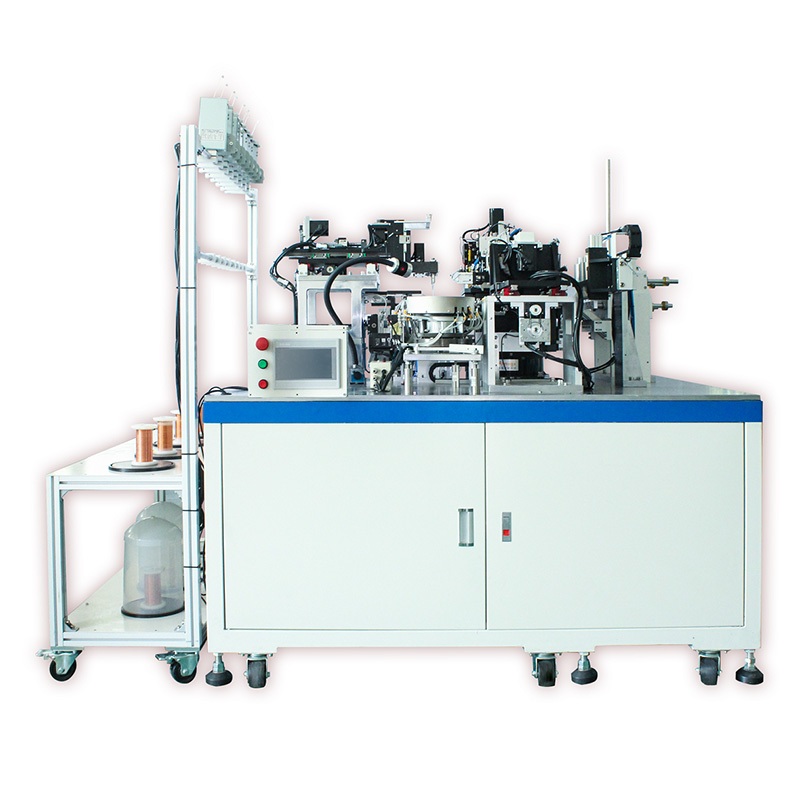

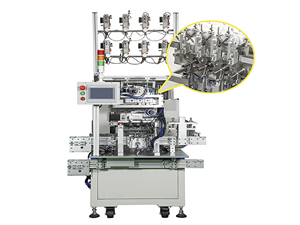

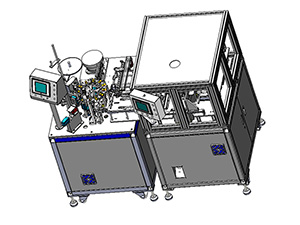

Common Mode Choke Coil Winding Machine

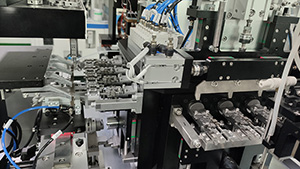

This winding machine is specially designed for winding coils on common mode choke. To achieve high efficiency and great precision, the servo motor is used for driving winding spindles, XYZ axis and turntable. Due to the high precision servo motor, the inductor core can be conveyed by the turntable to the different stations for different processes including winding and spot welding in a precise and automated manner. The common mode choke coil winding machine comes with a vibratory bowl feeder, ensuring a consistent and accurate inductor core feeding. Coil winding types are available with single and double wire winding. Accurate count is achieved by a PLC control system. The max. winding speed reaches up to1200 pieces/h.

| Feeding Mode | Vibratory bowl feeder |

| Winding Mode | Main spindle rotation winding |

| Application | 4532, 3225, 2012 common mode chokes |

| Applicable Wire Diameter | 0.04-0.10mm |

| Applicable number of Wires wound | Single wire or double wires winding |

| Number of Spindles | Four Spindles |

| Drive Mode | Direct drive motor (four stations) |

| Spindle Speed | Max. 3000rpm |

| Machine Capacity | 1.0 Kpcs/H-1.3 Kpcs/H |

| Working Environment | -5 ℃ ~ 50 ℃ (no corrosive and harmful gas, no dust and other harsh environments) |

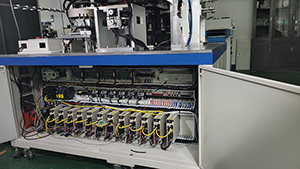

| Operation and Control Mode | Imported PLC control system, intuitive HMI screen for easy operation |

| Machine Size | L1600mm x W1450mm x H1800mm |

| Power Supply | single-phase AC220V, 50HZ |

| Air Supply | 0.5 ~ 0.7MPa |

| Power | 4.5KW |

| Machine Weight | about 700KG |

JDL has devoted itself in the field of electric motor rewind, serving an extensive portfolio from coil winding equipment to electrical safety test equipment.

For over a decade, JDL has been specialized in manufacturing and supplying engineering solutions and equipment to the wire processing and electrical industries. We strive to pay close attention to the needs of our customers and move forward by designing and producing optimal winding machines and peripheral equipment.

- Area B, Third Floor, No. 2 Nanjiang Industry, Tongsheng Community, Dalang Street, Longhua District, Shenzhen

- +86-755-29370700